Preface

PV modules are the smallest, indivisible module of PV cells with packaging and internal connections that can provide DC power independently. It is the core component of the PV power generation system and consists of eight core materials. Today, let's learn about the science popularization knowledge of the eight core materials of PV modules!

01. Cell

The cell is the core component of the module, mainly used to convert light energy into electricity. The cell can be series-connected and parallel-connected to achieve a certain rated output power and voltage to form a PV module. PV modules are combined to form PV arrays, which are connected with the controller, cell bank, inverter and other modules to form a PV power generation system.

Solar cells are classified by raw material as monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Crystalline silicon cell technology is based on silicon wafer, and generates electricity by photogenerated carrier separation according to PN junction. According to the differences of raw materials and cell preparation technology, the crystalline silicon cells can be divided into P-type cells and N-type cells. P-type silicon wafer is made by doping boron element in silicon material. The traditional AL-BSF (aluminum back-field) and PERC technology are used to prepare P-type cell. The N-type silicon wafer is made by doping phosphorus in silicon material. There are more N-type cell preparation technologies, including PERC, TOPCon, IBC and HJT.

Wherein, the heterojunction cell is one of N-type cells, which has the advantages of high conversion efficiency, high power generation capacity, low temperature coefficient, no PID and LID, simple preparation process, high bifacial power generation efficiency and the like. With the continuous breakthrough of cell technology and the continuous acceleration of industry process, heterojunction technology is expected to become the next generation mainstream cell technology.

▲AKCOME 210mm half-cut HJT Cell

02. Glass

PV glass is a kind of soda-lime silicate glass, which is mainly used for packaging PV modules. PV glass will directly affect the power generation efficiency and service life of PV modules.

PV glass is typically low iron tempered glass or semi-tempered glass with the following properties. Firstly, good permeability. Light transmittance is a key factor affecting the conversion efficiency of PV cells. PV glasses need to have high light transmittance and high reflectivity to 1200nm infrared light. Secondly, the mechanical strength is high. It can withstand the wind pressure of 2400Pa and the snow pressure of 5400Pa, playing the role of support and protection. Thirdly, the durability is good. Affected by climate and geographical location, the modules shall be operated in the open air and in the environment with large temperature difference between day and night, and need to have corrosion and weather resistance qualities.

HJT cell modules are generally encapsulated with ultra-white, low-iron toughened glass, which has high light transmission and fewer impurities, and is less likely to self-detonate. The front side of Akcome’s heterojunction cell modules are made of toughened coated glass, which enhances light transmission.

03. Adhesive Film

PV encapsulation adhesive film is an important component of the PV module and is located on both sides of the cell. The primary function of the adhesive film is to bond the cell with the glass and the back plate. Secondly, the adhesive film can play a role of packaging protection, protect the cell circuit from being interfered by the external environment, and prolong the service life of the module. In addition, the encapsulation adhesive film can enhance the light transmittance of the PV module so as to improve the power generation efficiency of the module. Finally, the adhesive film also serves as a structural support and positioning of the cell during module production, storage, installation and use.

According to the material, the mainstream adhesive film mainly includes EVA, POE, EPE and PVB. EVA film is the mainstream PV encapsulation film with good light transmittance, good processing performance, stable supply and low cost, but has the defects of high water vapor permeability, low impact resistance, unstable PID resistance and the like. POE film has low water vapor permeability and good anti-PID performance. It is suitable for the encapsulation of double glass modules and N-type modules, but the processing property is poor and the cost is high.

Akcome heterojunction double-glass module is packaged with POE adhesive film, with high water resistance and high PID resistance, providing reliable guarantee for high-efficient heterojunction modules.

04. Back Plate

The PV back plate is encapsulating material that is used as back-side protection and is commonly used in single glass modules. The PV back plate can be divided into fluorine-containing back plate and non-fluorinated back plate. Fluorine-containing back plate includes TPT, TPE, TPC, CPC and non-fluorine back plate includes PET, PA/PO, etc.

The PV back plate is mainly used for resisting the erosion of materials such as cell slice, adhesive film and the like in the environments of damp and heat, plays a role in corrosion resistance, weather resistance, oxidation prevention and insulation protection, which can effectively prolong the service life of modules. The high reflectivity of the white back plate improves the conversion efficiency of the module. The high infrared reflectivity also facilitates the reduction of the module’s operating temperature.

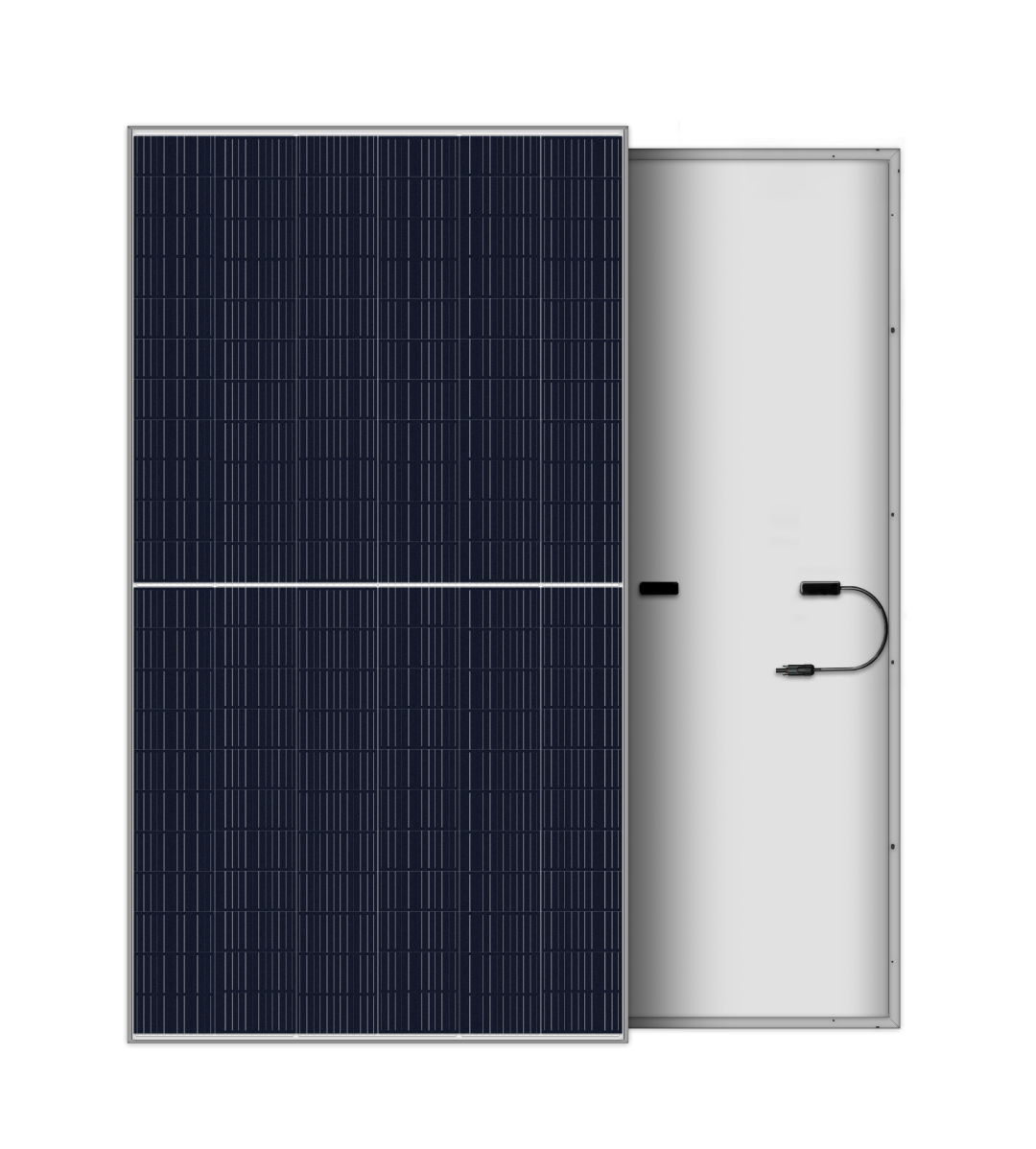

05. Frame

PV frame is a frame installed on the extension of glass, mainly used to fix and seal the solar cell module, so as to facilitate the transportation and installation of the PV module. The installation of the frame is favorable for protecting the glass edge and enhancing the sealing performance of the PV module. Meanwhile, the frame is a link carrier for carrying the module and the bracket, and the use of the frame can improve the mechanical strength and load resistance of the whole module, thereby prolonging the service life of the module.

Akcome's heterojunction high-efficiency modules mainly use aluminium frames as encapsulation material. Akcome Jiangyin production base provides professional PV aluminum frame business. After 17 years of innovation and development, the production capacity, production precision and quality of Akcome PV frames are among the leading in the industry. The PV aluminum frame business has also become the traditional advantageous business of Akcome.

06. Solder Strip

PV solder strip is a composite conductive material formed by coating tin-based solder on the surface of copper strip. It is applied to the series-connected or parallel-connected of PV cells and plays the role of current collection and conduction. It is an important material in the solder process of PV modules.

The PV solder strips are divided into interconnection strips and bus strips. The interconnection solder strip is used for connecting the PV cells and collecting and transmitting the current of the PV cells. Bus strips can be used to collect the current generated by the cell string and leading out to the junction box. The solder strip has a direct impact on current collection, which in turn affects the power and efficiency of the module.

In the early days of industry, flat solder strips were used, but with the development of the industry, high efficiency modules are now using round solder strips. Akcome HJT modules are now made with low temperature round wire solder strip featuring an oxygen-free copper core, the outer layer is soldered with tin-lead alloy, and low-temperature soldering flux is used for soldering at 165-190°C.

07. Silicone

Silicone is mainly used for bonding and sealing laminated glass PV modules, bonding frame and glass, junction box and back plate (or glass) for sealing and connecting. According to the different use position, the silicone is divided into sealant and potting adhesive. The sealant is used in the frame slot and at the bottom of the junction box and the back plate. The potting compound is generally used inside the junction box. It is mainly used to protect the internal circuit of the junction box.

08. Junction Box

The junction box mainly comprises a junction box cover, a sealing ring, a diode, a heat dissipation device, a box body, a wire and a connector. The main function of the junction box is to connect the power generated by the solar cell with the external circuit. It can play a role of sealing, waterproof and dustproof for the PV module lead-in line. The junction box also has the function of protecting the operation safety of the PV module system. In case of short circuit of the module, the junction box will automatically disconnect the short-circuit cell string to prevent the whole system from being burnt out.

Akcome high-efficiency modules mainly adopt divided junction boxes, which shall be fixed on the PV modules when in use. The pouring sealant shall be injected into the junction box, and sealant shall be applied to the edges to play a role in sealing and fixing.

Heures d'ouverture : 8:00-17:00 les jours de semaine

HQ: 0571-89089399

Sales: +86-512 8255 7328

Mail: modulesales@akcome.com

Siège social: salle 901, bâtiment 1, n° 1818-2, Wenyi West Road, rue Yuhang, district de Yuhang, ville de Hangzhou, province du Zhejiang